Adhesion remains one of the most critical properties in flexographic (flexo) printing. From film substrates to coated papers, modern flexo systems demand precise control over how well inks bond to various surfaces. At the core of this functionality lies the adhesion promoter-a critical additive that enables inks to adhere properly, especially in high-speed, high-volume printing environments.

In this guide, we focus on balancing two essential parameters in adhesion promoters: titanium content and viscosity. These properties, when optimized, can significantly improve print quality, press stability and long-term durability. Products like TA-10 and TPI-02, developed by manufacturers at Tridev Resins, provide a real-world benchmark for how adhesion promoters should be formulated for best-in-class results in flexo and gravure printing inks.

Understanding the Role of Adhesion Promoters in Flexo Inks

An adhesion promoter-also referred to as an adhesion enhancer-is typically an organometallic compound or modified polymer that increases the affinity of ink components to non-porous or low-energy substrates. In flexo systems, these substrates can include:

- BOPP (biaxially-oriented polypropylene)

- PET (polyethylene terephthalate)

- PE (polyethylene) films

- Metal foils and coated paper

These surfaces inherently resist ink adhesion, which is where adhesion enhancer play a pivotal role by improving interfacial bonding through chemical anchoring and surface wetting mechanisms.

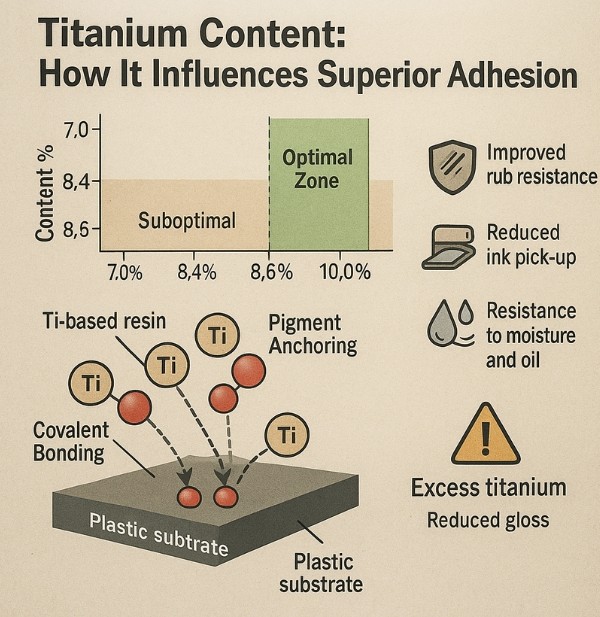

Titanium Content: How It Influences Superior Adhesion Mechanisms?

Titanium compounds are widely recognized for their catalytic and Superior adhesion in coating systems. In the case of flexo ink formulations:

- Titanium content between 8.4% and 8.6%, as found in TA-10 and TPI-02, is optimal for promoting strong adhesive bonding with plastic substrates.

- These compounds act at the molecular level to form covalent bonds with the substrate’s surface groups, anchoring pigment particles in place.

Proper titanium balance may:

- Improve rub resistance

- Reduce ink pick-up during lamination

- Enhance resistance to moisture, oils and packaging wear

However, excessive titanium may cause unwanted interactions with other ink components, impacting drying time and gloss. Therefore, precise formulation is essential to maintain a stable ink film.

Viscosity Considerations in Adhesion Promoter Performance

Viscosity, measured in seconds using a flow cup, determines how easily an ink or additive flows under specific conditions. TA-10 and TPI-02 both exhibit viscosities between 16-18 seconds, which is ideal for:

- Maintaining consistent ink laydown

- Ensuring smooth ink transfer through anilox rollers

- Preventing foaming or clogging during high-speed printing

In adhesive bonding, proper viscosity ensures:

- Optimal wetting of the substrate

- Even dispersion of titanium compounds

- Reduction of ink film defects such as pinholes or craters

If the viscosity is too low, the promoter may bleed or fail to adhere; if too high, it could increase ink tackiness and slow down press operations. Hence, viscosity adjustment must be synchronized with the ink’s base resin system and solvent ratio.

Comparative Product Insights: TA-10 vs TPI-02

Here’s a direct comparison of the two major adhesion promoter products used in flexo and gravure systems:

| Property | TA-10 | TPI-02 |

| Appearance | Pale Yellow Liquid | Pale Yellow Liquid |

| Titanium Content | 8.4 – 8.6% | 8.4 – 8.6% |

| Viscosity @30°C | 16 – 18 Sec (FCB4) | 16 – 18 Sec (FCB4) |

| Key Applications | Flexo & Gravure Inks | Flexo Inks, OPV |

Both grades perform similarly in adhesion enhancement, but TPI-02 is optimized for broader use, including overprint varnish (OPV), where surface clarity and bonding need to coexist without haziness or tackiness.

Ink System Compatibility with Adhesion Enhancer: Getting the Balance Right

An effective adhesion promoter should integrate seamlessly with the base ink system, which may be formulated using:

- Nitrocellulose (NC) for fast-drying inks

- Polyurethane resins for flexibility

- Polyamide binders for solvent compatibility

To achieve superior adhesion, your formulation should:

- Match promoter viscosity with the ink resin system

- Add adhesion enhancer post-pigment dispersion to prevent flocculation

- Test adhesion with industry-standard tape and rub tests at various drying times

Typically, 0.5% to 2% of the adhesion promoter is sufficient, but trial formulations should be conducted to identify the sweet spot between print quality and operational stability.

Superior Adhesion: Best Practices for Press Stability and Print Quality

To avoid defects such as ghosting, ink lift or smear, follow these formulation and application tips:

- Pre-mix the adhesion promoter with a compatible solvent before adding to the main ink batch

- Avoid over-shearing during mixing, which may alter the promoter’s molecular structure

- Maintain press temperatures below 40°C, as high heat may lead to premature solvent loss or reduced adhesion

- Perform pilot trials using standard substrates and drying conditions before full-scale printing

Proper formulation also helps to reduce ink rejection, minimize press downtime and ensure repeatable print performance across production shifts.

Conclusion

Balancing titanium content and viscosity in adhesion promoters is not just about hitting target specs-it’s about optimizing adhesion, press performance and substrate compatibility. Whether using TA-10 or TPI-02, ensuring the right concentration, blending method and interaction with ink resins will lead to superior adhesion results in flexo and gravure systems.

Adhesion promoters are often overlooked components, but their role in ink systems is foundational to achieving consistent, durable and high-quality prints-especially on challenging substrates.

- Rosin Modified Phenolic Resins Applications in Sheet Fed, Web Offset & Lithographic Inks

- Water-Based Acrylic Emulsions Dual Protection: Abrasion Resistance and Bio-Shielding for Coatings

- Formulation Tips for Adhesion Promoter: Balancing Titanium Content and Viscosity in Flexo Ink Systems

- Tailored Phenolic Resin Viscosity: Enhancing Varnish and Low-Temperature Ink Performance

- How Polyamide Resins Enhance Corrosion Resistance and Structural Coating Performance?